Overheating is one of the CPU problems due to overheating of its parts which poses dangers to the entire system of the computer.

This blog talks about the role of heat sinks in protecting your computer if CPU overheats, allowing for maximum efficiency and the safety of the important parts and components.

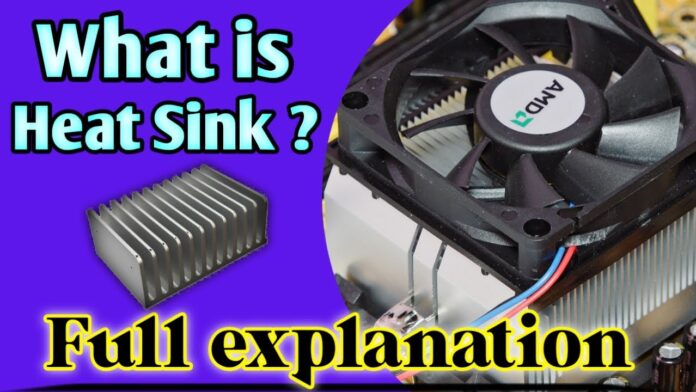

What is a heat sink?

The heat sink is a piece of metal which is mounted on top of the computer chip such as CPU and draws power away from the components by the heat rising through a series of finns.

Heat sinks are, by themselves, passive, that is, without any moving parts. In most cases, the heat sink is, then, combined with a wind turbine which blows the hot air away or a liquid cooling solution that takes the heat halfway through the pipes.

What is the function of a heat sink?

A CPU is heating up due to the fact that some of its parts generate heat. When the heatsink is not there the heat that is generated by components stay in the CPU which will burn it.

Since most of the components are made of electronic chips, they quick absorb heat. If they are exposed to too much heat, they get damaged and hence, they become useless which cause a risk to the performance of high-end computers.

The cooling of a CPU is of utmost essence because it cools even if you use it for several hours. It is intended to absorb the heat you CPU radiates and then to dissipate the heat away from its parts. Heat transfer can occur because the heat sink has fins which increases the surface area during the heat transfer.

A heat sink has to be well connected to the source of heat so as to ensure maximum cooling.

Heat sinks use a thermal conductor to transfer the heat into the fins which have larger surface areas and thus disperse the heat all around the computer

What Is the Main Parts of a Heat Sink?

A heat sink is quite a basic attachment. Listed below are the five components that make up a typical heat sink:

The fact that the data always contains false and junk items acquiring the accurate data is extremely difficult.

- Base

Thermal conductivity base generally is a flat block or sheet of material with high thermal conductivity. The base usually has a constant cross-sectional thickness; however, a cross-sectional profile designed to maximize the heat transfer for a particular geometry of the heat source is also possible. The base is generally screwed on to the heat source using mounting hardware and thermal paste.

- Fins

Fins attached to the heat sink base facilitate the process of heat transfer to the environs fluid. These fins are tailored to maximize the surface where the heat sink meets the fluid. The larger the surface area the faster the heat transfer rate.

The fins may be either an integral part of the base or may be joined by utilization of one of the various methods of joining such as via a compression process. Fin shape and distribution strongly influence the heat transfer coefficient.

- Heat Pipes

A heat pipe is engineered to move heat down its axis. Heat pipes can be included into the standard heat sinks and heat spreaders through the press fitting, soldering, and thermally conductive epoxy to increase the heat transfer effectiveness. They work using a phase change method whereby the fluid in them changes to vapor at the heat source, then moves along the heat pipe axis to where it gets cooled and turns back into liquid via the condensation process. - Thermal Interface Material

Products that transport heat between two or more solid mating surfaces are known as thermal interface materials, or TIMs. These materials, for instance, can act as gap fillers between the two mating surfaces of semiconductor devices and a heat sink to help with thermal management.

- Mounting Hardware

Heat sinks can be securely fastened to the heat sources they are aimed at using different mounting techniques. Adhesive with high thermal conductivity is used for direct stick to heat source for small heat sink. Such method is commonly applied to smaller PCB components. For larger heat sinks, regular screws may be applied or, alternatively, spring loaded push pins are used to maximize the contact pressure between the heat source and the heat sink.

What Materials Are Heat Sinks Composed of Heat sinks are manufactured using materials of high thermal conductivity. The most common ones among them are given in the second section.

What Materials Are Heat Sinks Made Of?

- Aluminum: Aluminum is a lightweight, cheap material that has good thermal conductivity. It is a common material used in the heat sinks of electronic equipment’s like computers and LED lights.

- Copper: Excellent thermal conductivity of copper allows its application on more susceptible components like CPU of computers.

- Aluminum Alloys: The pure aluminum is difficult to work with as it is too soft. The aluminum alloys like 1050 have increased strength not significantly affecting heat transfer while the 6 series alloys are even stronger and sacrificing thermal conductivity.

- Graphite: Conductivity of Graphite is almost equal to that of copper but it is considerably lighter.

- Diamond: The heat conductivity of diamond is much better than that of copper despite the latter’s significantly lower price. It is normally used in semiconductor applications.

Active Heat Sinks vs. Passive Heat Sinks

Heat sinks are mostly employed in active, passive or hybrid combinations.

– Passive heat sinks work thanks to natural convection, that is, the buoyancy of hot air movement is the driving force of the airflow generated throughout the whole heat sink system. The novelty is that these systems do not need separate schemes for power supply or heat removal to function. Though passive heat sinks do not work well in removing heat from a system as compared to active heat sinks.

– Forced air active heat sinks increase fluid flow over the hot area. The most common source of forced air is a fan, blower or even movement of the whole object―for example, cooling of the engine of a motorcycle by air passing along the heat sink fins built into the engine. An instance of a fan passing air by heat sink is the PC fan that will turn on the moment your computer gets heated. Fan draws air across the heat sink that results in bringing more unheated air across the heat sink surface thus increasing the total thermal gradient across heat sink system иallowing more heat to get out of the whole system.

– Merging some features of passive and active heat sinks are hybrid heat sinks. These are not so common, and they are mainly controlled by control system that provides cooling on the basis of required temperature. At the cooler system run modes, the active forced air source is inactive, supplying cooling only passively. Heat sink system cool mechanism activates as the heat source heats to a point beyond the initial point. It increases the cooling capacity to meet the demand of more cooling power.

What is heat sink paste?

Heat sink compounds–also called thermal grease, thermal compound, CPU grease, heat paste, heat sink paste, and thermal interface material–is a sticky paste that is used as an interface between CPU heat sinks and heat sources.

A thermal interface material is used to fill in gaps between the CPU or other heat generating parts, and the mechanical heat sink. The mechanical heat sink is overlayed on the CPU. Heatsinks attached to the CPU draw heat away and the thermal energy then dissipates through the fin while the air is blown across via a fan to cool the CPU down.

Conclusion

The CPU heat sinks contribute significantly to removal of heat from the CPU and thereby keeping the CPU from overheating by protecting the critical surfaces of individual parts and components.

Performance of a computer is restricted, when and where it is most needed, to a great degree by the CPU overheating. At Trenton our boards have custom as well as standard heat sinks and blower fans from Dynatron that offer cooling on the components and the system as a whole.

Our engineers dedicate countless hours into configuring a solution with the best heat dissipation approach that routes the heat out of the chassis for optimum performance across all conditions.

FAQs

1. Heat sink biology is what?

Scientific definitions heat sinks

Such an environment possesses the capacity to absorb heat from substances in it and whose thermal contact it has without the appreciable change in its own temperature and without its own phase change.

2. What is heat sink in server?

Heat sinks and cooling fans are used to cool the server CPUs, hard disks, control circuits, chipsets, power supply units and other components via convection mode of heat transfer. A heat sink is a component which is used to get rid of the heat generated by electronic chips or processors.