On the off chance that you know about 3D printing, you have an overall thought of additive producing is. As modest gadgets have become progressively more open, you have likely seen 3D printing referred to in the news, TV shows or motion pictures. The Harvard Business Review has called “the three dimensional Printing Revolution.” It’s vital to take note of, these portrayals of 3D printing are misrepresented and too broad this standard status.

Albeit 3D printing and additive producing are frequently utilized reciprocally, they are not equivalent. Additive producing is a more extensive term used to portray fabricating procedures made in a comparable layering style. These assembling strategies are utilized to make all that from toys to shoes to the parts on a stream motor.

WHAT IS ADDITIVE MANUFACTURING?

Additive producing is the most common way of building actual items by layering materials like metal, plastic, or cement. A cycle utilizes unique programming and gear.

The product will initially make a plan known as a Computer-Aided Design (CAD). The hardware will then, at that point, take this CAD record and decisively layer material, making an actual portrayal of the CAD.

To clear up disarray on the various kinds of Additive producing, a bunch of norms were made that sort the various cycles. These classes were made by the International Organization for Standardization in 2010 and gave clear definitions to additive producing processes. These definitions worked on worldwide correspondence between the individuals who work in the business.

Here is the Types Of Additive Manufacturing

1. Tank photopolymerisation

Tank Photopolymerisation is otherwise called stereolithography. This kind of Additive fabricating utilizes a tank of fluid photopolymer pitch which is the way VAT photopolymerization accepted its name.

A form stage is brought down from the pitch’s top, moving lower, and a laser bar attracts a shape the gum, making a layer. The normal thickness of one layer is somewhere in the range of 0.025 and 0.5mm.After each layer of sap, it should then be restored utilizing bright (UV) light.

This course of photopolymerization utilizes engine controlled mirrors to coordinate the UV across the pitch surface, making it solidify. These means are rehashed to add layers.

For expanded exactness and finish, most hardware utilizes edges that go over each layer to eliminate deserts prior to applying and relieving the following layer. Utilizing a fluid makes a lot of exactness and detail in the completed venture; in any case, it misses the mark on underlying scaffolding given by different sorts of additive producing. This is rectified by adding support structures. Albeit the VAT photopolymerization process rushes to finish, the tidy up and present it is extensive on process time.

Tank Photopolymerisation is utilized in a few enterprises to make parts and items going from amplifiers to Nike shoes.

2. MATERIAL JETTING

With material streaming, the print head is over the stage, and material is stored onto the surface as beads. Many miniature beads are situated with charged diversion plates, giving expanded control and precision. These beads then, at that point, harden, making a layer. This is rehashed, developing layers.

The drops might be disseminated constantly or separately utilizing the Drop-on-Demand (DOD) strategy. This technique is like an inkjet printer. Material streaming should be possible with different materials, including polymers and waxes.

This sort of additive producing is exact, and you can involve numerous materials for one undertaking. Albeit precise, it isn’t the most effective technique as time is spent re-filling the supply that drains rapidly.

Material flying is frequently used to make sensible models or models.

3. Fastener Jetting

This kind of additive producing utilizes a folio and a powder-based material. This powder-based material is applied to the form stage with a roller, and afterward the print head stores the folio on top.

The fastener sticks the layers together and is ordinarily in fluid structure. Following a layer, the item is brought down on the stage. This is rehashed to make more layers until the item is done. While utilizing this interaction, you can utilize various materials, including polymers, pottery, and metals.

Fastener streaming is viewed as one of the speediest additive producing techniques and takes into consideration customization. For instance, assuming you require material of a particular quality, you can change the fastener powder proportion, or on the other hand if you need to make an item that has variety, you can do as such.

One of the downsides of folio streaming is the expansion in post-handling time, and it may not be the most ideal decision for making primary parts.

Folio flying is utilized in modern applications, dental and clinical gadgets, aviation parts, part projecting, extravagance applications, and that’s only the tip of the iceberg.

4. MATERIAL EXTRUSION

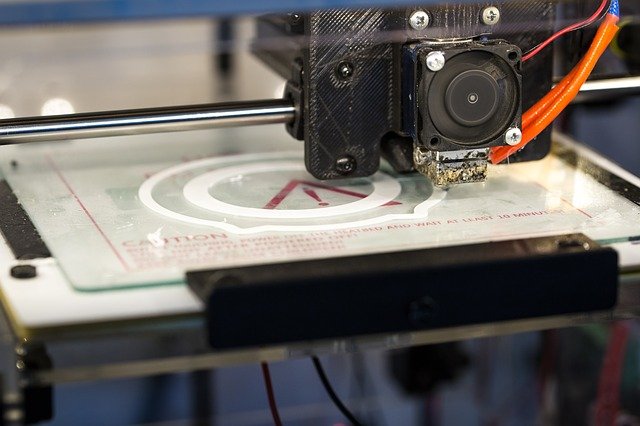

Material expulsion is a kind of additive producing process frequently utilized in reasonable at-home 3D printers where the material is drawn through a spout, warmed, and afterward kept in a constant stream. This spout moves along evenly and the stage climbs, down, and in an upward direction. This is the manner by which the layers are made. Since the material is warmed (softened) when it is applied, it breakers to the past layer. The holding between layers can likewise be controlled through temperature and synthetic specialists.

Albeit material expulsion is much of the time seen in modest models, it has numerous abilities. Polymers and plastics can be utilized, which offer solid underlying help. Nonetheless, there are likewise restrictions to this added substance producing process.

- Exactness is decreased as a result of the spout thickness.

- Material expulsion is additionally one of the more slow kinds of added substance fabricating.

- Numerous car organizations utilize material streaming to make fabricating gadgets utilized in sequential construction systems.

5. POWDER BED FUSION

For powder bed combination added substance producing, a layer of powder is applied to the stage. A nuclear power source like an electron pillar or laser intertwines the powder before a subsequent layer is applied with a roller or sharp edge. This it is then rehashed to layer process.

There are slight varieties inside powder bed combination, including:

- Particular Laser Melting (SLM)

- Particular Laser Sintering (SLS)

- Electron Beam Melting (EBM)

- Direct Metal Laser Sintering (DMLS)

Regardless of the distinctions between these variations, all powder bed combination fabricating happens in a close vacuum, pre-warmed chamber with latent gas. Metals and polymer powder materials can be utilized, which go about as a help structure, making it an appropriate sort for models and visual models.

There are a few drawbacks to the powder bed combination strategy as it requires more opportunity to finish projects; nonetheless, this added substance fabricating process is as yet utilized in different ventures, including flight, to make portions of a stream motor.