Medical masks are a very popular product in today’s life which are suitable for all ages and extremely useful in protecting human health. Besides, the disease situation from the Corona virus is complicated when there is a global spread leading to a shortage of quantity. In order to improve the above problem, face mask production lines in Vietnam continuously increase production to serve domestic consumers as well as export to abroad. Let’s find out how many types of medical mask production lines there are and where to buy 2D medical mask production lines in this post!

-

Materials for making medical masks.

The ingredients for the mask are extremely important because they directly determine the quality of the products because only high quality products can protect the user’s health in the best way. The ingredients needed to create a complete mask include:

- Non-woven fabric: This fabric is made up of synthetic resin particles and bonded together by a binder. Synthetic plastic particles are spun and combined into thin fabrics. Nonwoven fabrics provide specific functions such as absorbency, liquid repellency, elasticity, tension, softness, durability, fire resistance, washability, cushioning, heat insulation, sound insulation, filter, used as a bacterial and aseptic barrier. Environmentally friendly is also a great advantage that we cannot help but mention.

- Antibacterial filter cloth: The antibacterial filter cloth is used as the middle liner which has the function of filtering out fine dust. According to information from experts, the ability to filter dust and bacteria of this fabric up to 99%. Therefore, it is possible to effectively prevent respiratory diseases.

- Nose wire: Nose wire is used to shape and keep the mask snugly, cover the user’s face and limit the skin’s contact with the outside environment. When wearing, we just need to bend it to the bridge of the nose.

- Straps: In addition to the aforementioned parts, straps are also extremely necessary in the manufacturing process of medical masks. Cotton and Spandex are two materials used to make straps because they have good elasticity, they do not hurt our ears or leave any prints when we wear for a long time. Raw materials which are used for the production of medical masks Uniduc always have partners with offices in countries producing fabrics that are qualified to buy fabrics at the factory, we ensure the supply of materials with price and best quality, ensuring stable production for customers.

-

Types of medical mask production lines.

- Semi-automatic mask production lines.

The semi-automatic medical mask production line includes the following machines: mask body making machine, strap press machine, strap welding machine,… to create a complete mask. They operate in a semi-automatic mechanism which means there is still a need for human assistance.

The use of semi-automatic lines saves a lot of initial investment costs. However, the manufactured products may fail if the worker does not have much experience in operating and handling the machine. So companies that manufacture medical masks, when using this type of line, they need to focus on selecting and training employees before they are put to work.

- Fully automatic mask production lines.

This type of line is now widely used. They include machines that produce finished products in a fully automatic mechanism without the need for operator intervention. This line can create masks from 1 – 5 layers for both children and adults.

Compared with semi-automatic lines, fully automatic lines have many strengths, namely:

- Increased productivity: an automatic system can produce 10 – 50 cases per day equivalent to 100-200 pieces/minute. In contrast, semi-automatic systems only achieve half of the above capacity.

- Labor saving: if the semi-automatic line needs a lot of workers to monitor and operate the machines, the automatic line only needs 1 – 2 people to arrange finished products.

- Quiet operation: machines in automatic lines operate more smoothly than semi-automatic lines.

- Lower defect rate: as a result, the defect rate in the automated medical mask export production system is 2% lower. Because the machine has integrated programmable control system and has electronic sensor eye.

III. Where should we buy 2D medical mask production lines from?

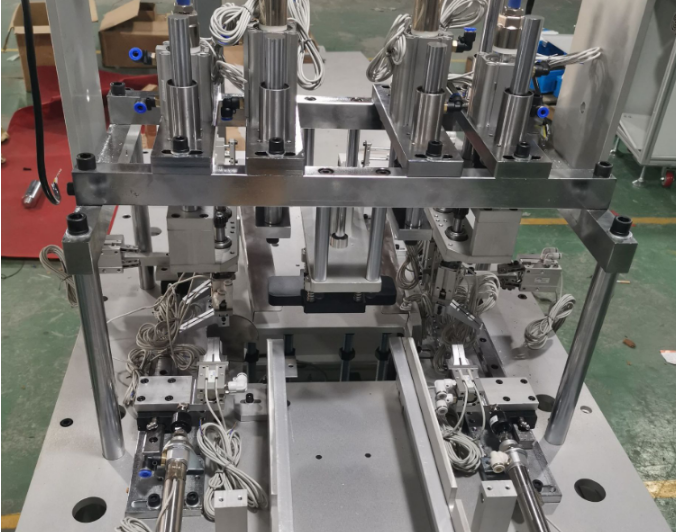

With the recent development of covid 19 and in the coming time, the bad conditions at the border gate are not good in order to avoid the spread of disease, it may take a very long time for goods to be available, leading to a shortage of imported machines from China. This is a serious shortage of machine supply. Uniduc has developed a system of automatic mask production lines with higher automatic levels and a much cheaper price than machines imported from China due to the epidemic lack of machine supplies. The automatic mask production lines processed and assembled by will be available after 25 – 30 days from the date you place your order. Uniduc 2D medical mask production lines have the following advantages:

- Uniduc products are warranted for 2 years. In the first year, we will come for free maintenance and grease after every 2 months of use.

- Stable productivity from 60 pieces/minute and upgrading on old systems of 150 pieces/minute. (The ability to upgrade increases productivity on older systems).

- An active replacement and repair facility is available. Uniduc has precision mechanical processing for Japan, since then, we also have experience in manufacturing and processing sanitary products as well as good quality steel for customers.

- Best quality mechanical equipment such as the use of health-safe silicone rollers, bearings and the finest air pistons for even precision quality.

- Electrical equipment originating from Japan: PLC industrial computers, motors, heaters,… are of major brands such as Misubishi, Yaskawa, Omron.

- Welding mask with ultrasonic welding technology, with new high-yield ultrasonic welding machine.

- The low cost of the machine helps you to spend a low initial investment cost which helps you get back capital faster than the Chinese line investment due to out of stock. (Low cost due to domestic production is the advantage of the mask production lines in Uniduc). Compared to Chinese lines, our lines are 500-600 million lower.

- Since Uniduc’s production line is made in Vietnam, they are always available earlier than imported lines. Line handover time is from 25 – 30 days.

- In order to standardize the production process of exporting clean masks, Uniduc’s side has designed the masking machine system, with updated features to help customers create the most cost-effective solution possible.

Uniduc is a great suggestion to consider. We cooperate with famous machinery brands to exclusively distribute products in addition to research and manufacture our own production lines for medical masks.

In short, the use of automatic production lines brings many benefits for businesses. In addition, there is an increase in product volume when respiratory diseases in general and Corona virus pneumonia in particular are becoming more and more serious, after this outbreak, people are also aware of the use of face masks more often to protect their health. This leads to the mask becoming a common product and essential for every family.

Above is some information about the medical mask production line that we hope to bring you the most necessary and useful information. If you have a need to learn about the production line as well as problems related to the production of medical masks, please contact Uniduc for advice and support in the best way.

Wish you success at work and happiness in life!

UNIDUC – AUTOMATION FACTORY CREATION

Address: 22 Street 54, Thao Dien, District 2, Ho Chi Minh, Viet Nam

Hotline: 089 6688 629 (Mr. Duc)

Email: Uniduc.jsc@gmail.com

Website: https://uniduc.com/en/