A pump that delivers a large amount of fluid disconnected by a period of no drainage is known as a positive displacement pump. The objective of positive displacement pump is to deliver and measure high accuracy.

In positive displacement pumps, the thrust exerted by the moving parts of the pump during each pump cycle delivers a certain amount of fluid.

The fluid flows into the enlarged cavity and discharges the same quantity of fluid when this cavity contracts. Thus, the pump maintains a constant flow rate. If the delivery pressure fluctuates over a wide range, a positive displacement pump is best suitable, but the flow rate must be kept continuous.

This type of pump doesn’t have an impeller, but transfers flow from the inlet side to the outlet side based on reciprocating components.

These types of pumps have constant flow rates and speed. Therefore, they are also known as volumetric pumps.

These pumps have multiple types such as piston pumps, plunger pumps, peristaltic pump, rotary pumps, screw pumps, reciprocating pumps, gear pumps, and diaphragm pumps. All of these types work on the basis of the principle of positive displacement. In the next section, we are going to discuss different types of positive displacement pumps.

Types of Positive Displacement Pumps

1) Reciprocating Pumps

The liquid flows from the inlet to the outlet of the pump.

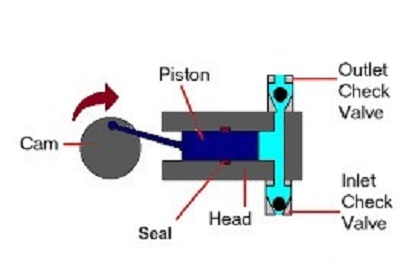

The piston, piston, and diaphragm move alternately to draw liquid from the suction port and push it into the cylinder to dispense a certain amount of liquid.

- Some reciprocating pumps have an expansion chamber on the inlet side and a contraction chamber on the outlet side. The liquid is drawn into the cavity as it expands and drains out when the cavity begins to shrink.

- The categories of reciprocating pumps range from simple (1 cylinder) to 4-stage (4) and higher. Most of these types have double (2) or triple (3) cylinders.

- Can be driven manually, with steam, air, or with a motorized belt.

- Most commonly used as a boiler feedwater pump in the 19th century. Today it is also used in pumps for highly viscous liquids such as heavy fuel oil and concrete, as well as in special applications that require liquids with low flow and high resistance.

2) Screw Pump

Screw-type positive displacement pumps use one or more screws to move liquids or solids through the screw shaft. It rotates in a cylindrical cavity and thus moves the material along the screw axis.

One of the advantages is that the pumped fluid moves axially without loss of flow and there is no turbulence, which prevents the viscous fluid from foaming.

3) Lobe Pump

It uses paddle elements and both elements are driven by their respective external gears.

They are available in single, double, 3- or 4-leaf structures.

The particle size pumped by the rotary lobe pump is much larger than any other positive displacement pump.

4) Diaphragm Pump

It is a reciprocating piston pump that pumps with a flexible diaphragm attached, as shown in the picture above.

The main advantage of diaphragm pumps is that they will not leak as long as the diaphragm is not damaged.

The pump output is proportional to the diaphragm diameter, stroke, and stroke speed.

5) Rotary Positive Displacement Pumps

In this positive displacement pump, the rotary motion moves the liquid from the inlet to the outlet of the pump.

Rotary pumps are classified based on the type of part that actually moves the fluid, and the type of gearbox, type of cams, type of vanes, and type of screw are very popular.

Where are positive displacement pumps used?

Low acquisition and operating costs are advantages of positive displacement pumps over other types. These pumps are suitable for high viscosity applications. No matter how the pressure changes, the system achieves a constant flow. That is, these pumps are used in applications that require accurate flow rates. Positive displacement pump applications include high-pressure cleaning, spraying/cleaning, water treatment, oil production, irrigation, refueling and injection, beverage dispensers, etc. Chemical, food, hygiene, pharmaceutical, and biotechnology applications also benefit from positive displacement pumps.

How does a positive displacement pump work?

The one end of the pump has an inlet that has expanding cavity while the other end has an outlet that has a reducing cavity.

- As the suction chamber starts increasing, a certain amount of liquid flows from the basin into the positive displacement pump.

- After suction, the piston starts moving inside the cylinder and pressurizes the liquid.

- When the cavity decreases, the liquid starts discharging from the outlet of the pump.

- After the above process, the compressed liquid transfers to the desired area.

Positive Displacement Pump Protection

Positive displacement pumps are generally equipped with a relief valve in front of the discharge valve to protect the pump and its discharge line from excess pressure. The displacement pump delivers at the pressure required for the supply system. If the pump’s discharge valve is closed while the pump is running, or if other events (such as filter clogging) prevent system flow, the pressure relief valve prevents damage to the system and the pump.