Ultrasonic plastic welders are highly efficient tools widely utilized in manufacturing industries to join plastic materials. These devices harness high-frequency ultrasonic acoustic vibrations to create solid-state welds, making them indispensable for numerous precision-driven applications.

Ultrasonic plastic welders provide a cost-effective solution for joining plastic materials without the need for adhesives or solvents. Their ability to produce clean and environmentally friendly welds contributes to their widespread adoption across various sectors of the manufacturing industry. This article talks about the intricacies of an ultrasonic welder, including their mechanics, components, advantages, and future trends.

The Physics Behind Ultrasonic Plastic Welders

At the heart of ultrasonic plastic welders lies the conversion of electrical energy into mechanical vibrations. These vibrations occur at ultrasonic frequencies, typically between 20 and 40 kHz. The welding process commences when a transducer converts electrical energy into mechanical vibrations.

These vibrations are then transmitted to the plastic materials being welded through a sonotrode. The mechanical energy generates heat at the interface of the plastic materials, causing them to melt and fuse without requiring additional adhesives or solvents. This precise energy control facilitates efficient and clean welding, which is crucial for various industrial applications.

Key Components of an Ultrasonic Plastic Welder

An ultrasonic plastic welder comprises several critical components, each playing a vital role in the welding process:

- Transducer: Converts electrical energy into high-frequency mechanical vibrations.

- Booster: Modifies the amplitude of the vibrations to suit the welding requirements.

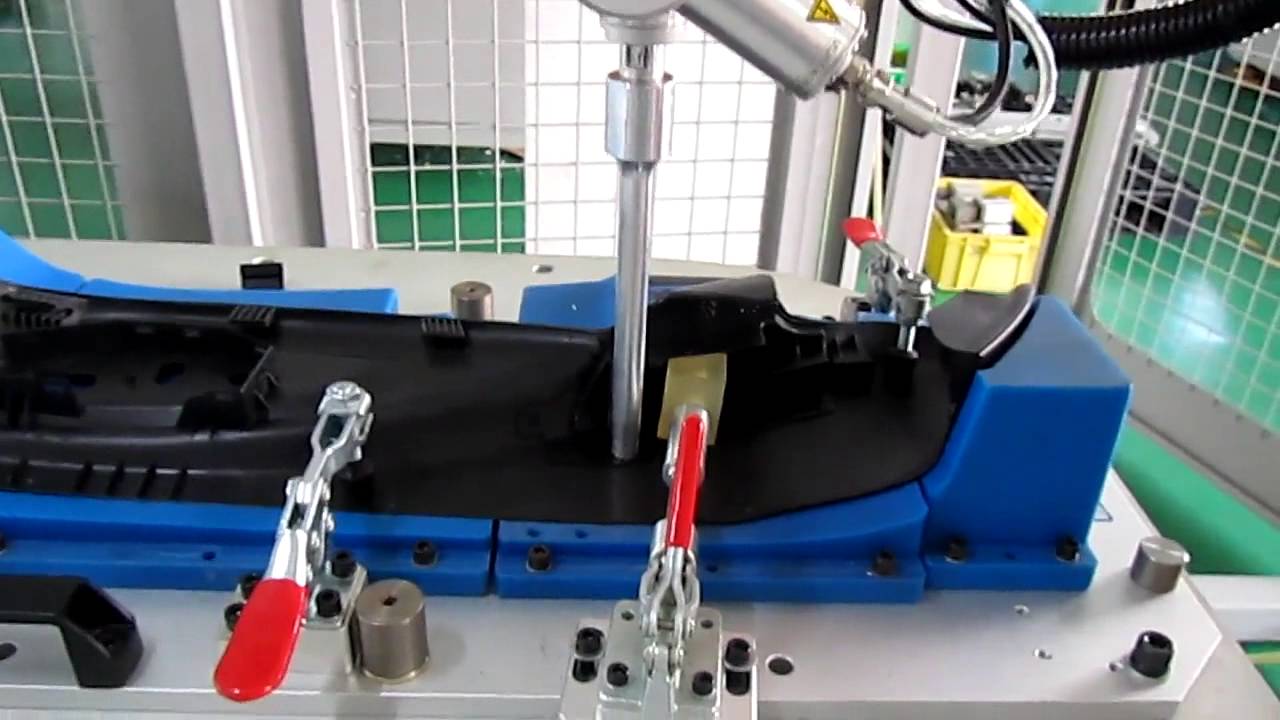

- Sonotrode (Horn): Directs the mechanical vibrations to the plastic materials being welded.

- Anvil: Provides support and alignment for the plastic materials during welding.

- Control Unit: Manages the welding parameters, including frequency, amplitude, and duration.

Each component must be precisely designed and calibrated to ensure efficient energy transfer and create a strong weld. The synergy between these components is crucial for achieving optimal welding performance.

Ultrasonic Plastic Welding Process Explained

The ultrasonic plastic welding process involves several steps to ensure precise and reliable welds:

- Preparation: The plastic materials to be welded are cleaned and aligned properly.

- Clamping: The plastic materials are clamped together between the sonotrode and the anvil.

- Application of Vibrations: The control unit activates the transducer, generating ultrasonic vibrations.

- Welding Phase: The mechanical vibrations cause localized heating at the plastic material interface, melting the surfaces.

- Cooling: Once the plastic materials fuse, the vibrations stop, and the weld cools and solidifies under pressure.

This step-by-step process allows for consistent quality and repeatability in welding operations, making it suitable for high-volume production. Understanding each stage helps in troubleshooting and optimizing the welding process.

Advantages of Ultrasonic Plastic Welders

Ultrasonic plastic welders offer numerous benefits, making them a preferred choice in various industries:

- Speed: The process is rapid, often completed in seconds, leading to high production rates.

- Precision: The ability to control welding parameters ensures consistent and precise welds.

- Cleanliness: As no adhesives or solvents are required, the process is clean and environmentally friendly.

- Strength: Welds produced by ultrasonic plastic welders are robust, often stronger than the original materials.

These advantages contribute to the widespread adoption of ultrasonic plastic welders in manufacturing, particularly in industries requiring high precision and reliability. The efficiency and cleanliness of the process make them especially appealing in today’s environmentally conscious market.

Applications in Various Industries

The versatility and efficiency of ultrasonic plastic welders make them applicable across diverse sectors:

- Automotive: Used for assembling interior and exterior plastic components, wiring harnesses, and electronic housings.

- Medical: Employed in the manufacturing of medical devices, such as catheters, filters, and surgical instruments, where hygiene and precision are critical.

- Electronics: Ideal for assembling small plastic electronic components, circuit boards, and housings without damaging sensitive parts.

- Packaging: This is used to seal blister packs, tubes, and other types of plastic packaging, ensuring tamper-evident and airtight seals.

Ultrasonic plastic welders’ adaptability to different plastic materials and ability to produce high-strength bonds make them invaluable in these industries. Each application benefits from the unique advantages of ultrasonic plastic welders, enhancing product quality and manufacturing efficiency.

Consideration and Solutions in Ultrasonic Plastic Welders

Despite their advantages, ultrasonic plastic welders can present challenges which require specific solutions:

- Material Compatibility: Not all plastic materials are suitable for ultrasonic plastic welding. Identifying compatible materials and understanding their behavior under ultrasonic vibrations is crucial.

- Joint Design: Proper joint design is essential to ensure adequate energy transfer and robust welds.

- Equipment Calibration: Precise calibration of the welding equipment is necessary to achieve consistent results.

Addressing these challenges involves thorough testing, material analysis, and continuous ultrasonic plastic welding process monitoring. Solutions such as advanced joint design techniques and sophisticated calibration methods are constantly being developed to overcome these hurdles.

Future Trends in Ultrasonic Plastic Welder Technology

The future of ultrasonic plastic welders looks promising with ongoing advancements:

- Automation: Increasing integration of automation and robotics to enhance precision and productivity.

- Advanced Materials: Development of new plastic materials that respond better to ultrasonic welding.

- Smart Systems: Implementation of smart control systems that monitor and adjust welding parameters in real time for optimal results.

An ultrasonic welder is pivotal in modern manufacturing, offering efficient and precise solutions for joining plastic materials. Their ability to harness high-frequency ultrasonic vibrations to create strong, clean, and environmentally friendly welds has led to their widespread adoption across various industries. Despite challenges such as material compatibility and joint design, ongoing advancements in automation, materials, and intelligent systems promise further to enhance the capabilities and efficiency of ultrasonic plastic welders.