In computer numerical control (CNC) machining, the tools and equipment used play a pivotal role in achieving precision and efficiency in manufacturing.

According to Amastone, CNC tools are designed for various machining processes, including milling, drilling, cutting, and shaping, making them essential for producing parts across industries like automotive, aerospace, electronics, and more. For beginners looking to understand the essentials of CNC tools, this guide covers the fundamentals and what you need to know to get started.

Understanding CNC Tools and Their Functions

CNC tools refer to the attachments or inserts that perform specific functions within a CNC machine. Each tool has a unique purpose, designed to carry out precise tasks in metalworking, woodworking, and other materials. The main types include:

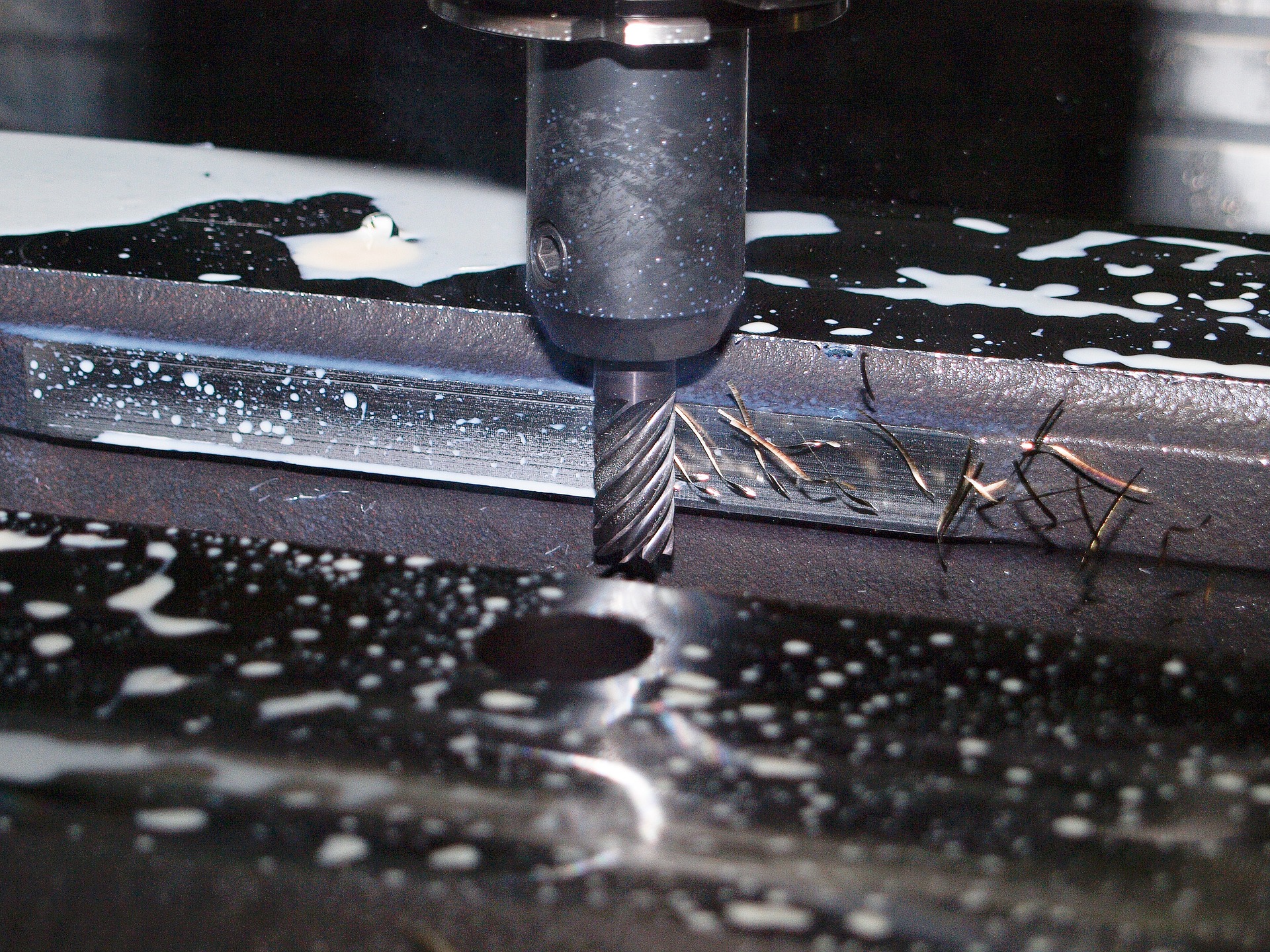

- End Mills: These are cutting tools used primarily in milling applications. They are capable of cutting in all directions and come in various shapes and sizes for different applications. Flat-end mills, for instance, are ideal for finishing surfaces, while ball-end mills are used for contouring or 3D machining.

- Drills: Drilling tools create holes in the workpiece, and in CNC machining, they ensure accuracy in diameter and depth. Twist drills are the most common type, but there are also specialized drills for materials like glass and plastic.

- Reamers: Reamers are used for enlarging existing holes to achieve specific tolerances and smooth finishes. Unlike drills, they don’t create holes from scratch but refine the diameter and roundness of pre-drilled holes.

- Taps and Thread Mills: These tools create internal threads in a pre-drilled hole, essential for screw assemblies. Taps are suitable for softer materials, while thread mills provide versatility in threading hard materials.

- Inserts: Inserts are small, replaceable cutting edges that fit into the tool holder and can handle high-pressure operations. Inserts come in various shapes (square, round, triangular) to accommodate different cuts.

Key CNC Tool Terms for Beginners

Familiarizing yourself with basic terminology can improve your understanding of CNC tools and help you make informed choices. Here are some terms to know:

- Tool Holder: This is the component that holds the tool within the machine spindle. It provides stability and precision during machining.

- Cutting Speed: This refers to the speed at which the cutting edge moves through the material. It impacts both the tool’s efficiency and lifespan.

- Feed Rate: The speed at which the workpiece is fed into the tool. Optimizing the feed rate is essential for achieving desired results and avoiding tool wear.

Choosing the Right CNC Tool for the Job

Selecting the correct tool can significantly impact the quality, speed, and cost of your machining project. Here are some factors to consider:

- Material of the Workpiece: Different tools are designed for different materials. For example, harder materials like steel require tools made of carbide, while softer materials like aluminum are suitable for high-speed steel tools.

- Type of Operation: Identify whether the operation involves cutting, drilling, or milling. Each process requires specific tools for optimal performance.

- Precision Requirements: If the project requires high precision, consider using specialized tools like reamers and high-accuracy end mills.

Basic Maintenance Tips for CNC Tools

Regular maintenance is crucial for keeping CNC tools in top condition. Here are some basic maintenance tips for beginners:

- Clean Tools Regularly: After each use, wipe down the tools to prevent debris buildup.

- Sharpen Cutting Edges: Dull edges reduce efficiency and can damage the workpiece. Sharpen tools as needed.

- Inspect for Wear and Tear: Regularly check for cracks, dull edges, or misalignment in tool holders.

Understanding CNC tools is fundamental for any beginner in machining. By knowing the types of tools, their functions, and how to maintain them, you’ll set a solid foundation for creating precise, quality parts in any machining project.