Introduction

In the realm of electronic design, managing heat effectively is crucial to ensure device reliability and longevity. Metal Core Printed Circuit Boards (MCPCBs) are specifically crafted to address this challenge.

This article explores the unique role of MCPCBs in enhancing heat dissipation and the significant benefits they bring to electronic devices.

What is an MCPCB?

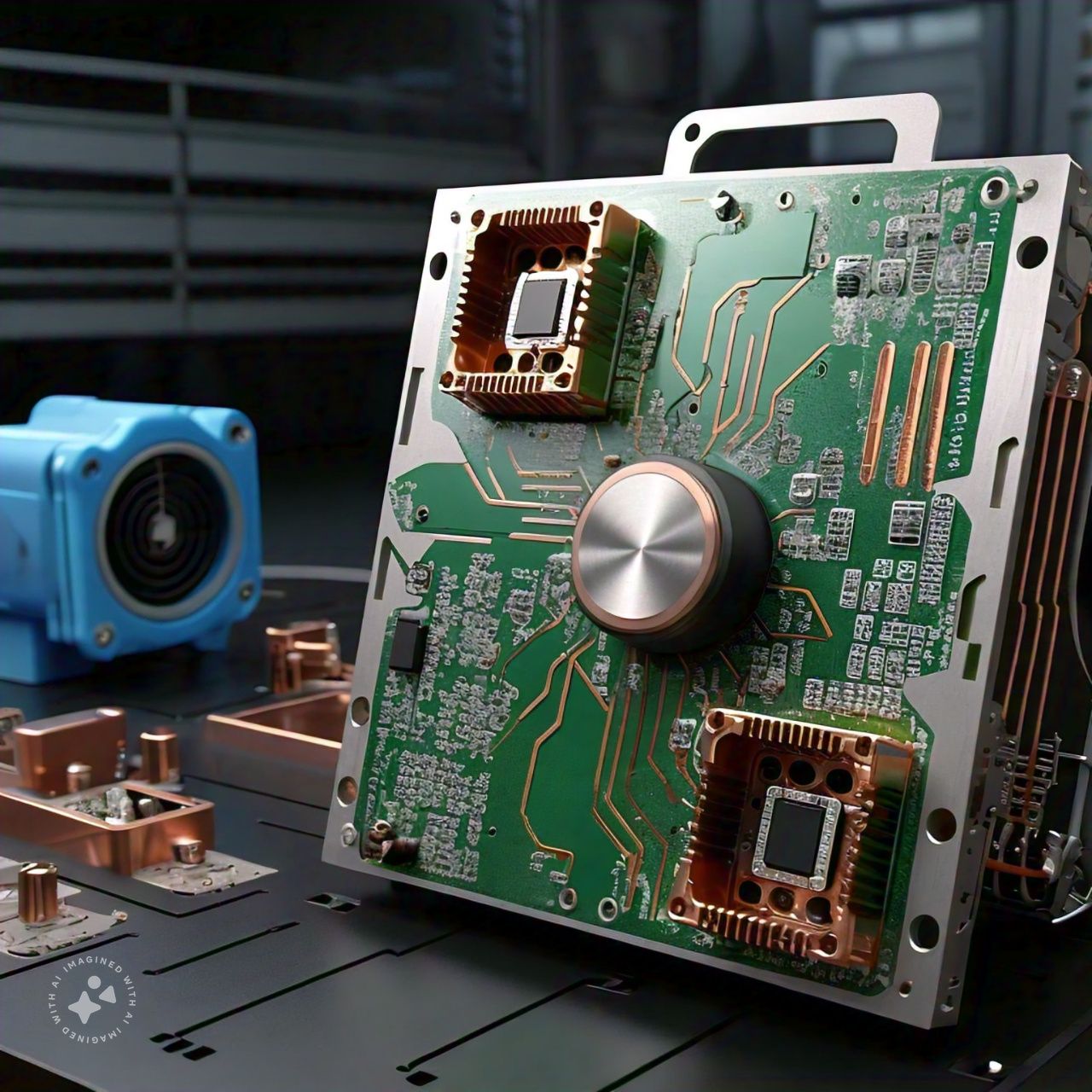

An MCPCB consists of a metal core, which can be aluminum, copper, or a mix of special alloys. This core is integral to the PCB’s ability to conduct heat away from vital components that generate significant amounts of heat during operation.

Unlike traditional PCBs that use non-conductive materials like fiberglass, MCPCBs integrate a metal layer that drastically improves heat dissipation.

Structure of MCPCBs

The typical MCPCB is comprised of a metal core, a thermal dielectric layer, and the standard copper circuit layer.

The thermal dielectric layer serves a dual purpose: it insulates the board electrically from the metal core and conducts heat towards it.

This structure allows for efficient heat transfer from the electronic components to the metal base, which then disperses it effectively.

Enhancing Heat Dissipation

MCPCBs manage heat through a process that channels thermal energy directly to the underlying metal core. This core, with its high thermal conductivity, swiftly moves heat away from components and towards cooler areas of the board or the surrounding environment.

Benefits of Improved Heat Dissipation

- Extended Component Life: Components on MCPCBs are at a reduced risk of overheating, which typically leads to failure or degraded performance.

- Enhanced Device Performance: Devices can operate at optimal levels without the risk of heat-related throttling.

- Simpler Cooling Requirements: The efficiency of MCPCBs often reduces the need for complex external cooling systems, which can lower design costs and space requirements.

MCPCBs vs. Standard PCBs

While traditional PCBs are constructed from materials like FR4, which has relatively poor thermal conductivity, MCPCBs provide a more efficient pathway for heat to escape, thanks to their metal cores. This distinction is crucial in applications where heat could otherwise degrade performance or cause failure.

Applications in Electronics

LED Lighting

In LED lighting systems, which are susceptible to efficiency loss and color shift when overheated, MCPCBs are invaluable. They maintain the temperature at optimal levels, ensuring consistent light output and color over time.

High-Power Electronics

Devices that handle high power levels, such as voltage regulators and power amplifiers, also benefit from the robust thermal management that MCPCBs offer. These applications often produce significant heat that can now be effectively managed with MCPCBs.

Emerging Uses

The use of MCPCBs is expanding into new areas like automotive electronics, where reliability under high-temperature conditions is essential.

Challenges and Considerations

Cost Factors

Although MCPCBs are more effective at managing heat, they come at a higher cost compared to standard PCBs. Designers must evaluate the thermal advantages against the increased expense.

Design Adjustments

Incorporating an MCPCB into a product may require adjustments in design practice to fully utilize its benefits while considering its thickness and thermal characteristics.

Conclusion

MCPCBs play a pivotal role in modern electronics by significantly improving heat dissipation, thus enhancing overall device performance and durability. Their ability to manage heat is becoming increasingly important as devices become smaller and more powerful.

For any engineer or designer working in fields where heat is a concern, understanding and utilizing MCPCBs is essential. As electronics continue to evolve, the importance of MCPCBs is likely to grow, marking them as a key component in the future of electronic design.